Attenuated Total Reflectance (ATR)

$99 Base price View My Quote RequestWhite Light Interferometry (WLI)

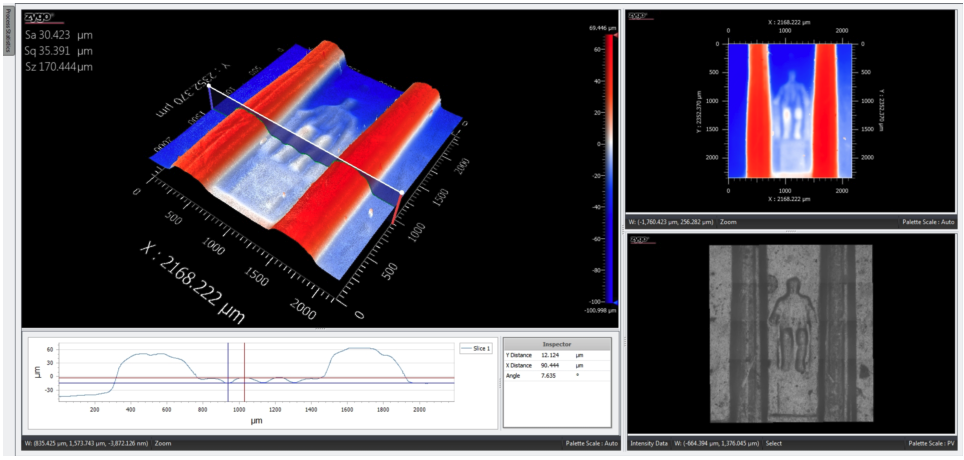

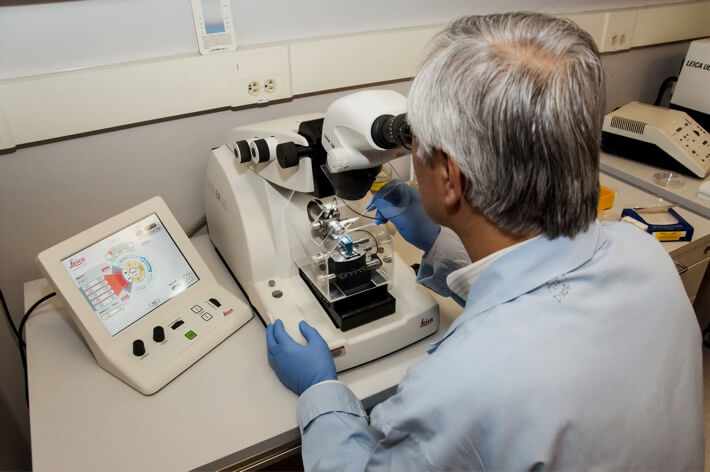

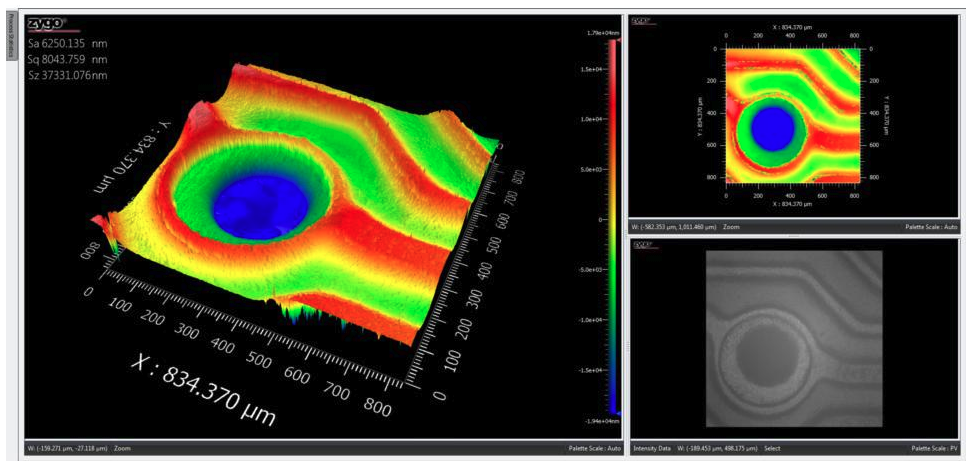

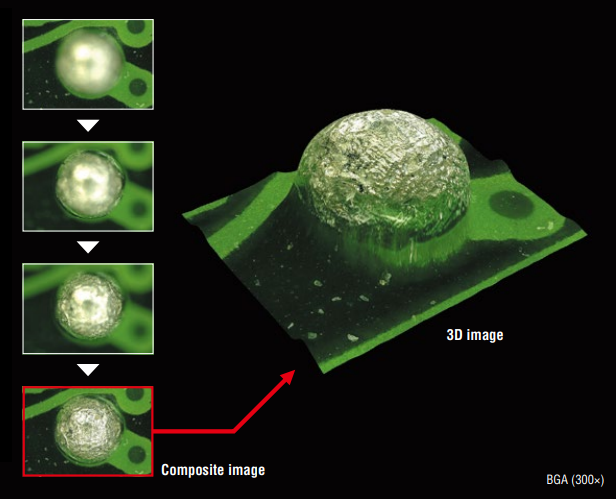

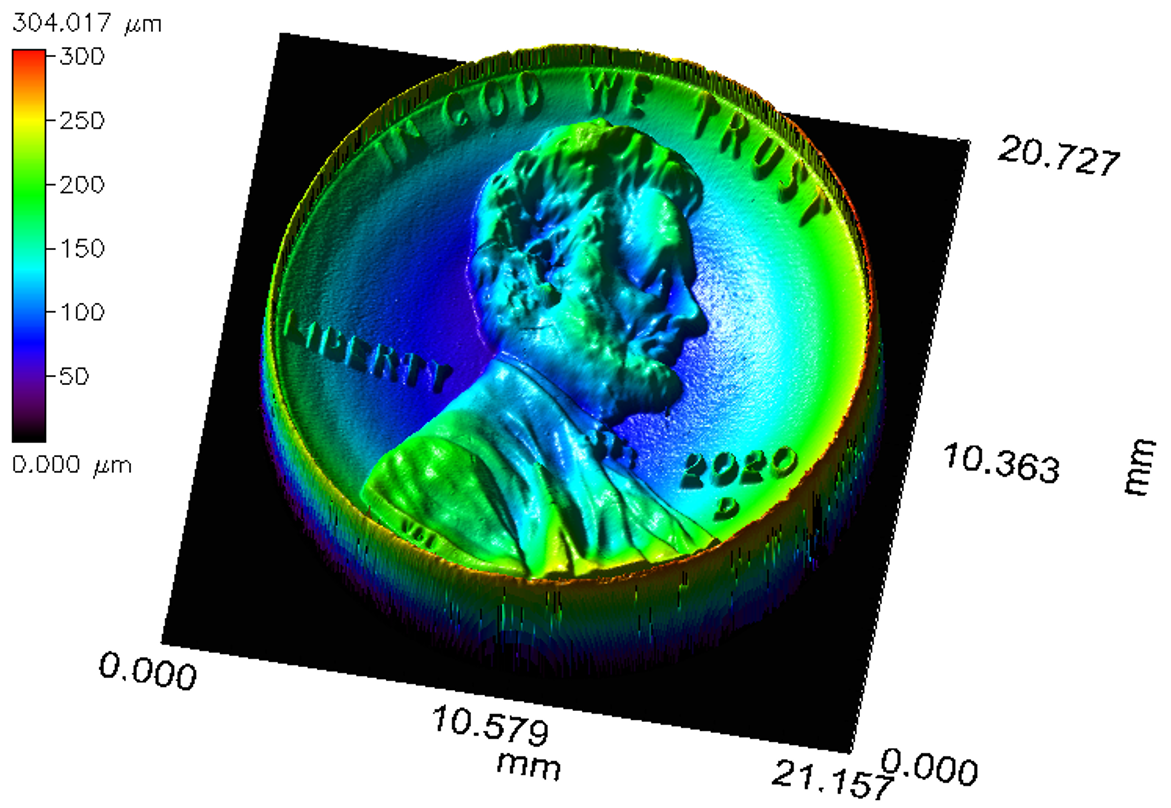

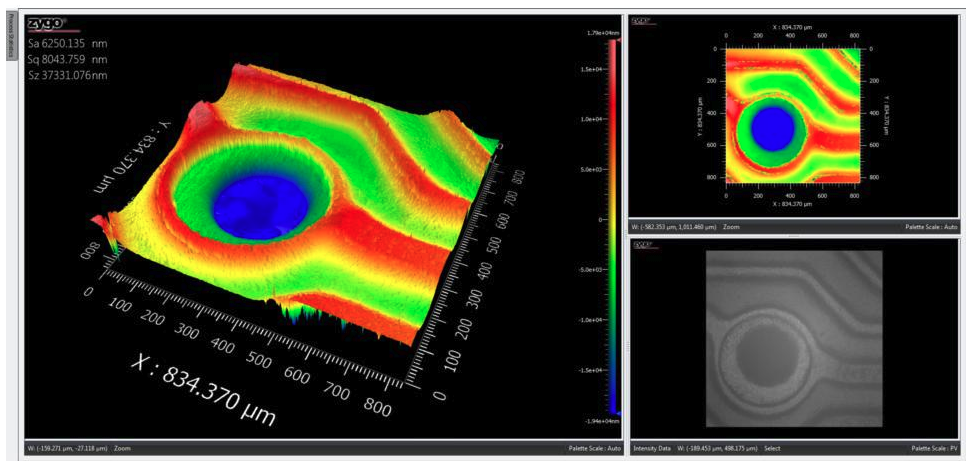

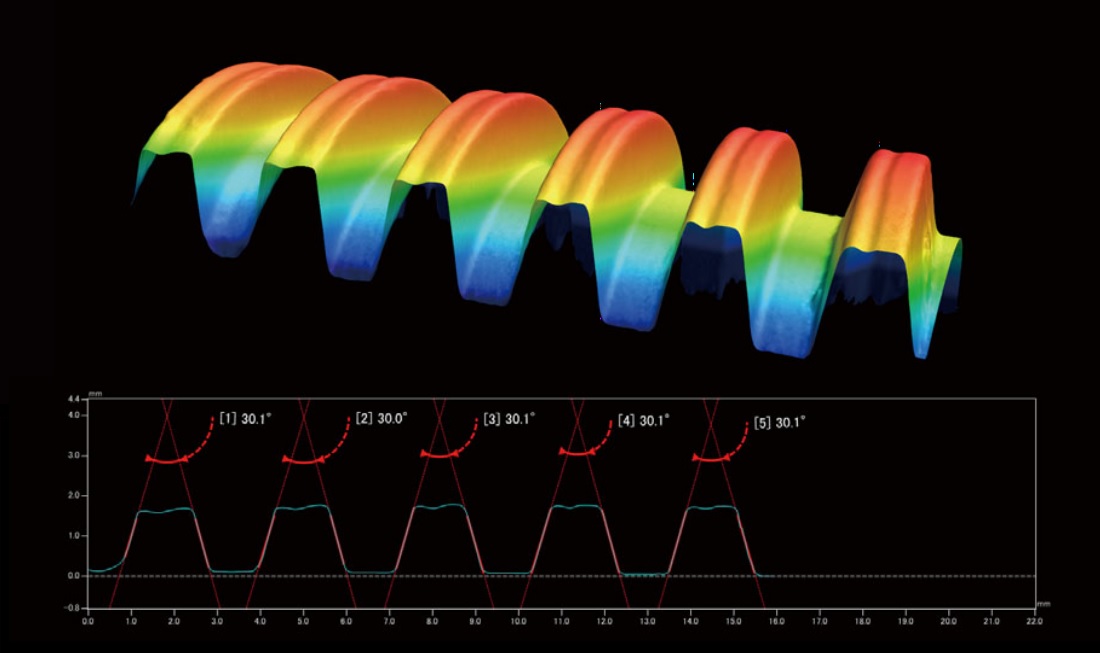

White light interferometry (WLI) is a nondestructive, non-contact, optical surface topography measurement which uses coherence scanning interferometry to generate 2D and 3D models of surface height.

- Rapid results

- Superior lateral resolution (limit is ~160 nm) as compared to chromatic confocal, Laser Confocal and Wide Area Patterned Light Mapping

- Nondestructive measurement

- High vertical resolution: ~1 nm

- Steep cut-offs and sharp topography angles impair WLI measurement accuracy around these features

- Interpretation of fringe changes can be difficult in certain types of samples

Technical Specifications:

Learn More:

WLI instruments use a white light source to illuminate the surface of the sample.

A beam-splitter divides the white light beam into two optical paths: one that reflects or scatters from the sample and one that reflects from a flat, known reference mirror. These two signal beams are then mixed together and the resulting image is projected onto a CCD image sensor.

The two beams, when mixed, form an interference pattern whose intensity can be related to the sample surface height: any difference in optical path length between the reference and sample beams changes the measured interference intensity at each scanned point, providing an indirect measure of the height variance in the sample.

The interference fringes are analyzed at each point to build up a 3D map of the sample surface.

Optical Microscopy and Profilometry Services

Overview: Mid-Range Optical Profilometry

White Paper: Atomic Force Microscopy for Advanced Optical...

Choosing the Right Surface Imaging Technique

Digital Optical Microscopy (VH Microscope)

Optical microscopy is ubiquitous in diverse fields within academic research and commercial industries. It is an affordable, rapid...

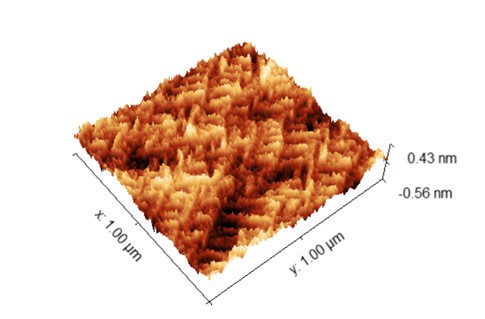

Atomic Force Microscopy (AFM)

AFM measures surface topography and certain material properties with sub-nm vertical resolution and atomic-level force sensitivity.

Chromatic Dispersion Profilometry (CWL)

Chromatic dispersion profilometry is a non-contact, nondestructive analytical technique used to measure surface topography. It is particularly well...

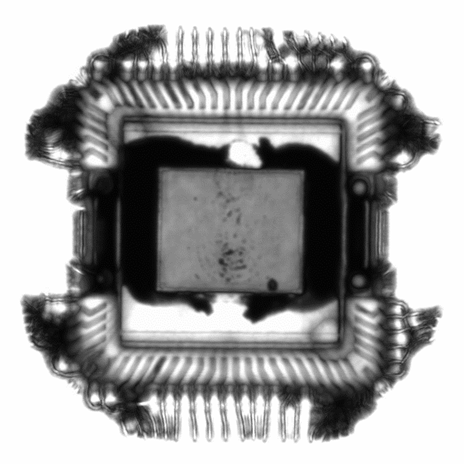

Scanning Acoustic Microscopy (SAM)

Scanning Acoustic Microscopy (SAM) is a non-destructive and non-invasive imaging technique which uses ultrasound signals to visualize the...

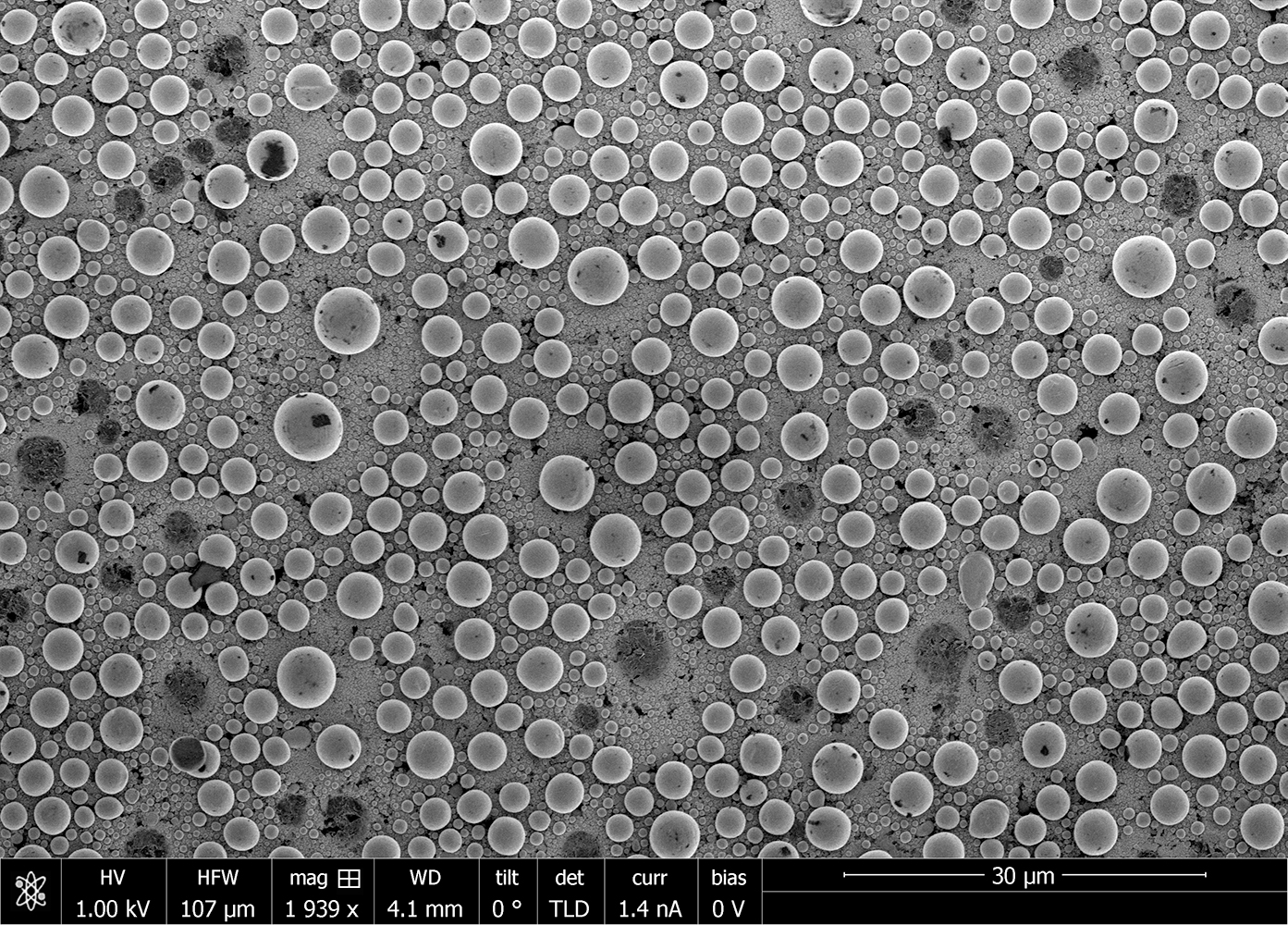

Scanning Electron Microscopy (SEM)

Scanning electron microscopy (SEM) is a surface imaging technique capable of achieving nm resolution on topographical features. Additionally,...

White Light Interferometry (WLI)

White light interferometry (WLI) is a nondestructive, non-contact, optical surface topography measurement which uses coherence scanning interferometry to...

Wide Area 3D Patterned Light Measurement (VR)

Wide Area 3D Patterned Light measurements encompass a class of optical profilometry techniques used to visualize the surface...