Attenuated Total Reflectance (ATR)

$99 Base price View My Quote RequestThermogravimetric Analysis (TGA)

Thermogravimetric analysis (TGA) is used to characterize sample volatility, as well as thermal stability and response.

- Exquisitely precise weight sensitivity – can detect sample mass changes < 0.1 ug

- Only a few milligrams of material is needed due to high instrument sensitivity

- Minimal sample prep

- Not available for measurements with temperatures below ~ 25 °C

Technical Specifications:

Learn More:

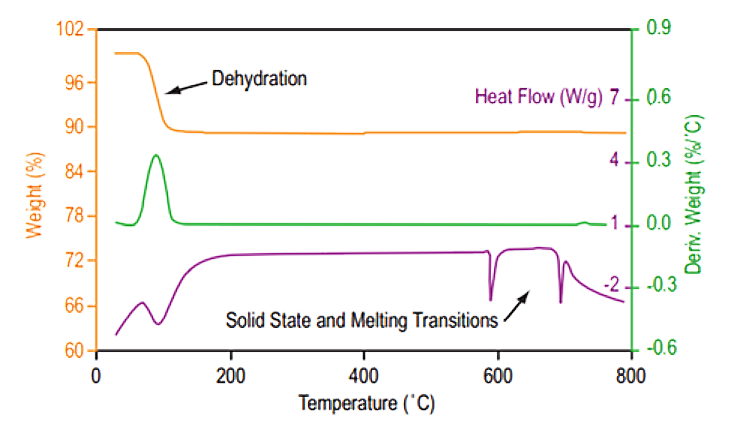

TGA and derivative TGA curves of sodium tungstate sample analyzed at 10 °C/min from ambient temperature to 800 °C.

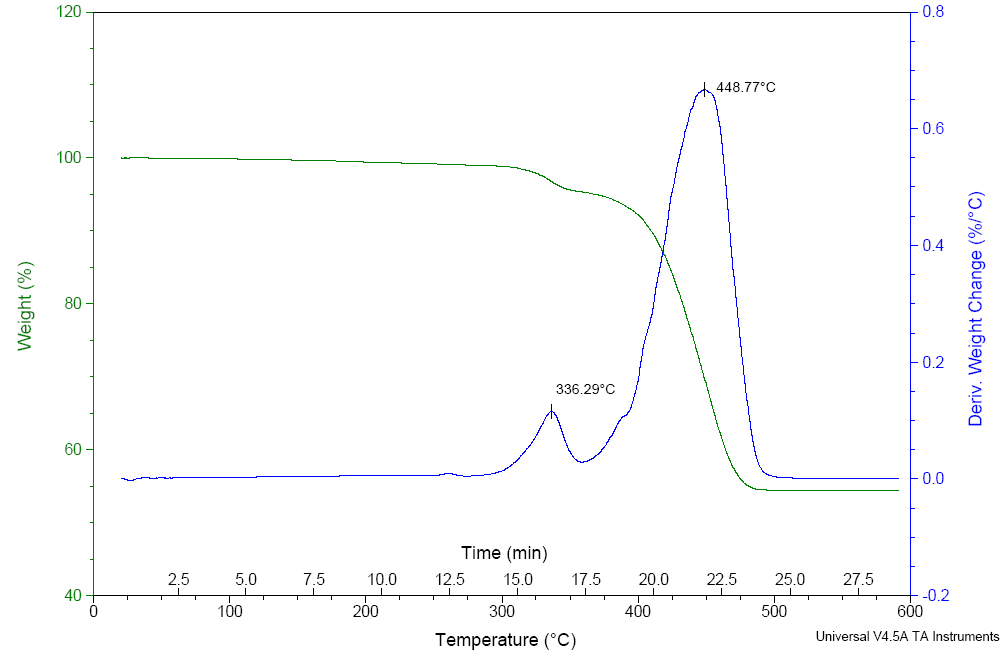

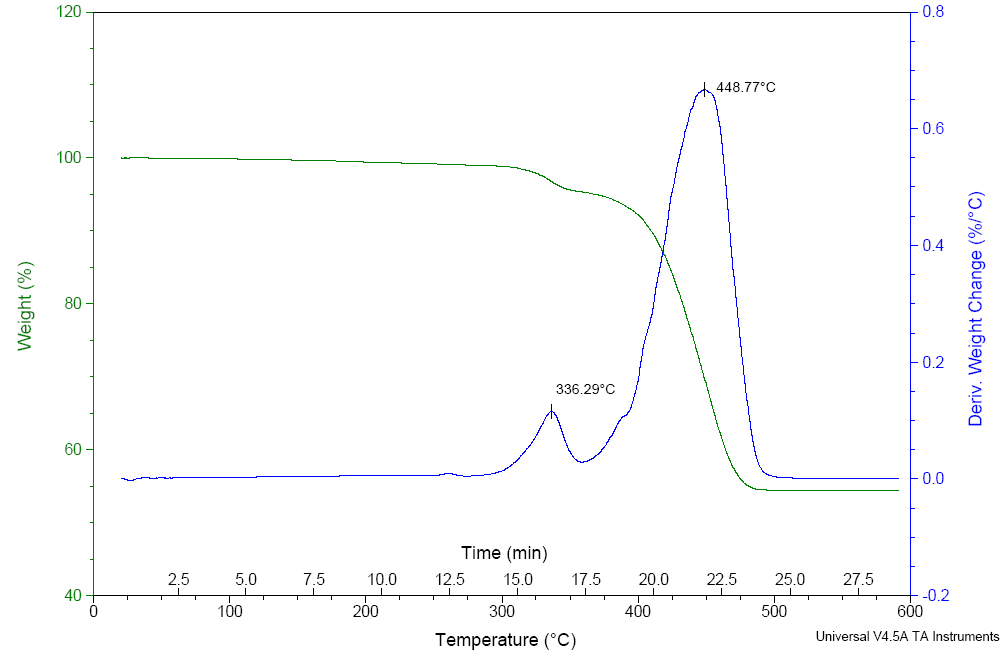

TGA Curves used in failure analysis of polyamide nylon (PA) enclosures on terminal block plug, which thermally degraded and caused critical instrument failure. Plot shows two different volatilization temperatures (peaks): suspected to be the casing itself and unknown filler.

TA Instruments TGA 5500

- Mass Sensitivity: 0.1 ug

- Temperature Range: ambient to 1200 °C

- Calorimetric Accuracy: ± 2% (based on metal standards)

- Controlled Heating Rate (up to 1000 °C): 0.1 to 500 °C / min

- Nitrogen Atmosphere

- View Instrument Spec Sheet

- Solids, powders, and semisolids accepted

- Minimum Sample Mass: ~ 0.5 g

- Sample material must have no chemical incompatibility with pan material; pan options:

- Platinum (Standard and High Temperature options available)

- Ceramic

- Alternative pan types can be procured if needed

- Powders preferred; non-powders must be able to be trimmed to fit TGA pan

- Safety datasheets of sample materials are required

When a sample reaches high enough temperatures, it undergoes chemical and physical transitions that affect its sediment mass.

A TGA system measures the minute changes in sample weight in a controlled thermal environment – usually, as heat is applied to the system. Alternatively, constant temperature experiments can be conducted to evaluate a material’s thermal stability over a set time period.

TGA instruments plot weight as a function of temperature and/or time, and analyzing these plots reveals several thermal properties of the material, including (but not limited to): thermal stability, heat resistance, volatility, and vaporization temperatures.

4 Targets for Optimization in a Battery Cell

Batteries Industry Solutions

Explore Thermal Characterization Techniques: TGA and DSC

TGA-IR Analysis Using the OMNIC Mercury TGA Software

Thermal Solutions: Characterization of Polyurethane by TGA and...

Characterization of EPDM Rubber by TGA and Hi-Res‘...

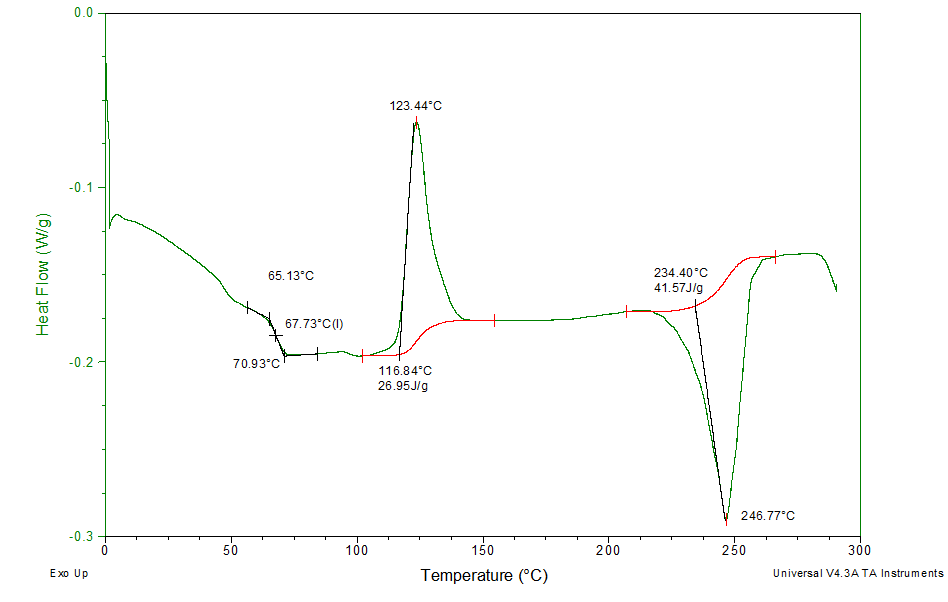

Differential Scanning Calorimetry (DSC)

DSC is a thermal analysis technique used to characterize a variety of temperature-dependent physical and chemical changes in...

Dynamical Mechanical Analysis (DMA)

Dynamic mechanical analysis (DMA) is used to study changes in the mechanical properties of a material under periodic...

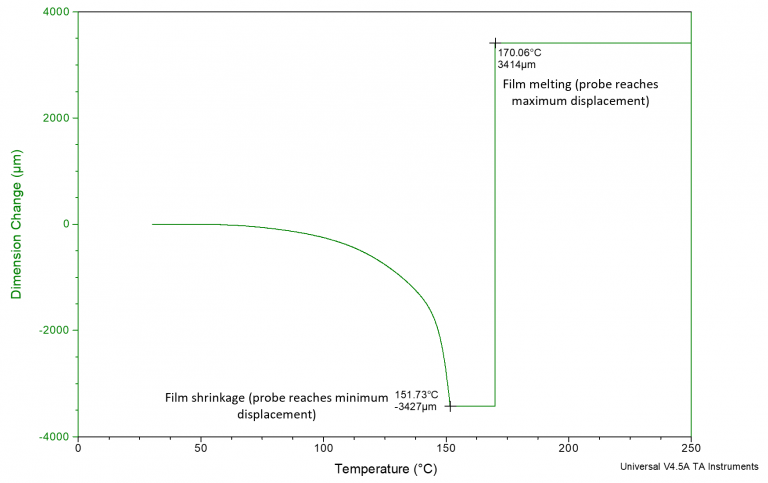

Thermomechanical Analysis (TMA)

Thermomechanical analysis (TMA) probes the response of the sample’s thermal, dynamic, and static-mechanical properties as temperature is changed...

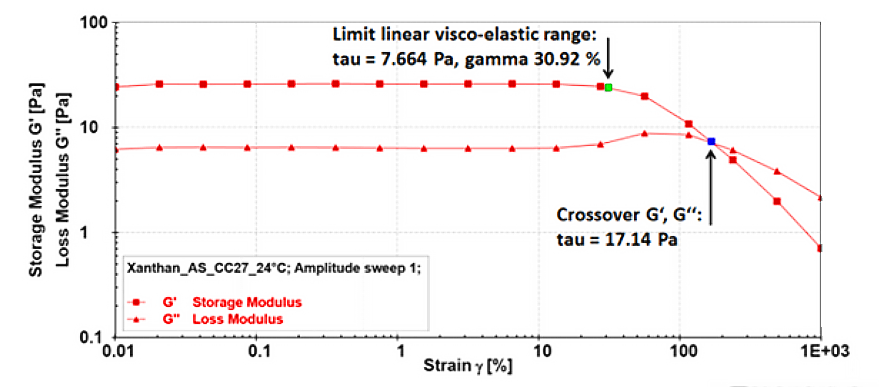

Rheometry (Rheology)

Rheometry measures the flow and deformation of materials in response to applied stress and strain to evaluate their...