Attenuated Total Reflectance (ATR)

$99 Base price View My Quote RequestSpectral Ellipsometry (SE)

Spectral ellipsometry (SE) – also called “Spectroscopic Ellipsometry” – is a non-contact, non-destructive optical characterization technique which can be used to assay numerous physical, optical, and topographical properties simultaneously and indirectly.

Using advanced modeling techniques to augment raw polarization state data, SE can richly characterize thin films, transparent materials, and semi-opaque layers.

- Data collection is generally quick and straightforward

- Precise and reproducible

- Very sensitive to ultra-thin films (single angstroms thick)

- Measured region on sample must be smooth and flat

- Complex modeling required to access most indirect properties – often requires extensive expertise to avoid analytical pitfalls

- Analysis of multi-layered samples sometimes requires fabrication of intermediate test samples with fewer layers in order to uniquely determine the properties of all layers present

Technical Specifications:

Learn More:

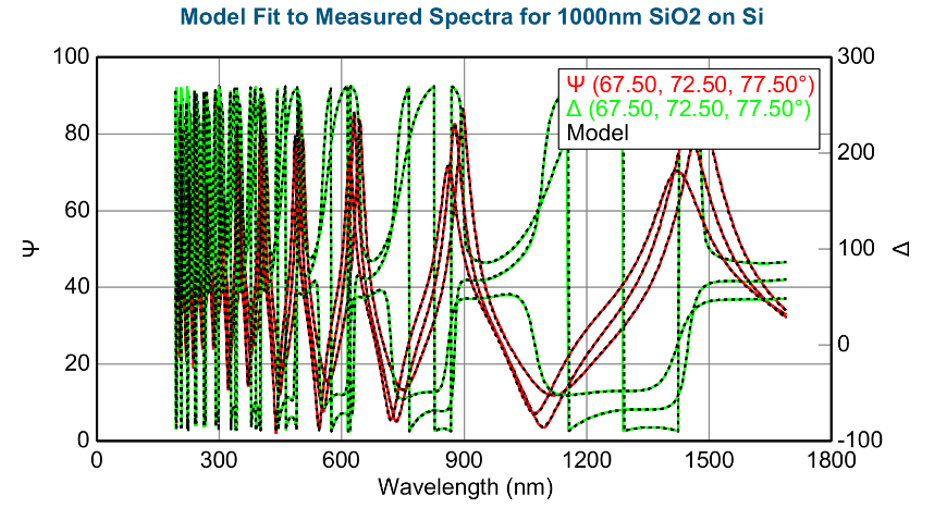

1000 nm SiO2 on Si spectroscopic ellipsometry raw data and model fit

Index of refraction mapped across nitride-rich SiNx film on a silicon wafer substrate

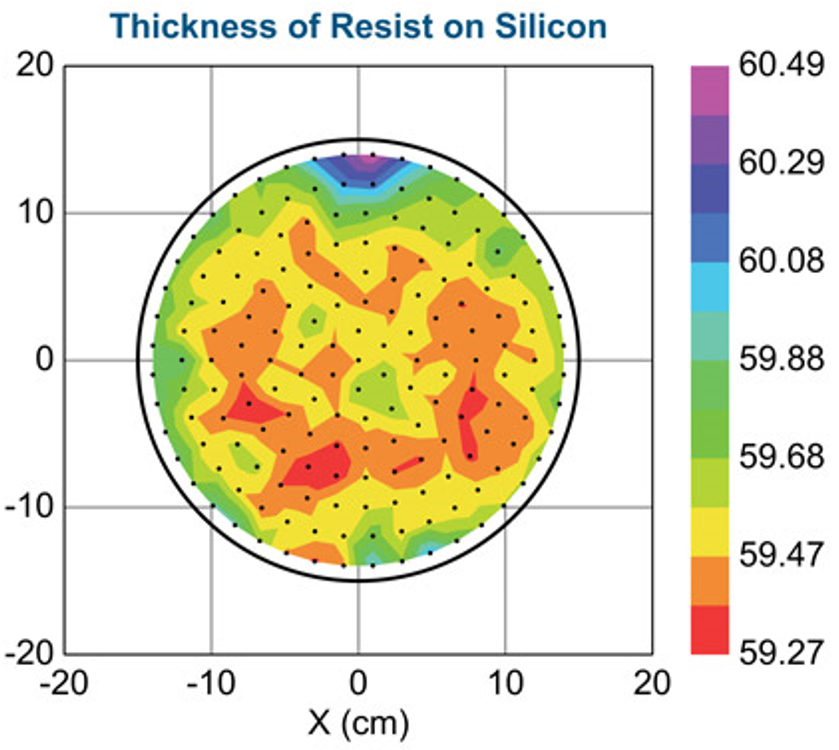

Thickness map of a resist coating on silicon wafer substrate

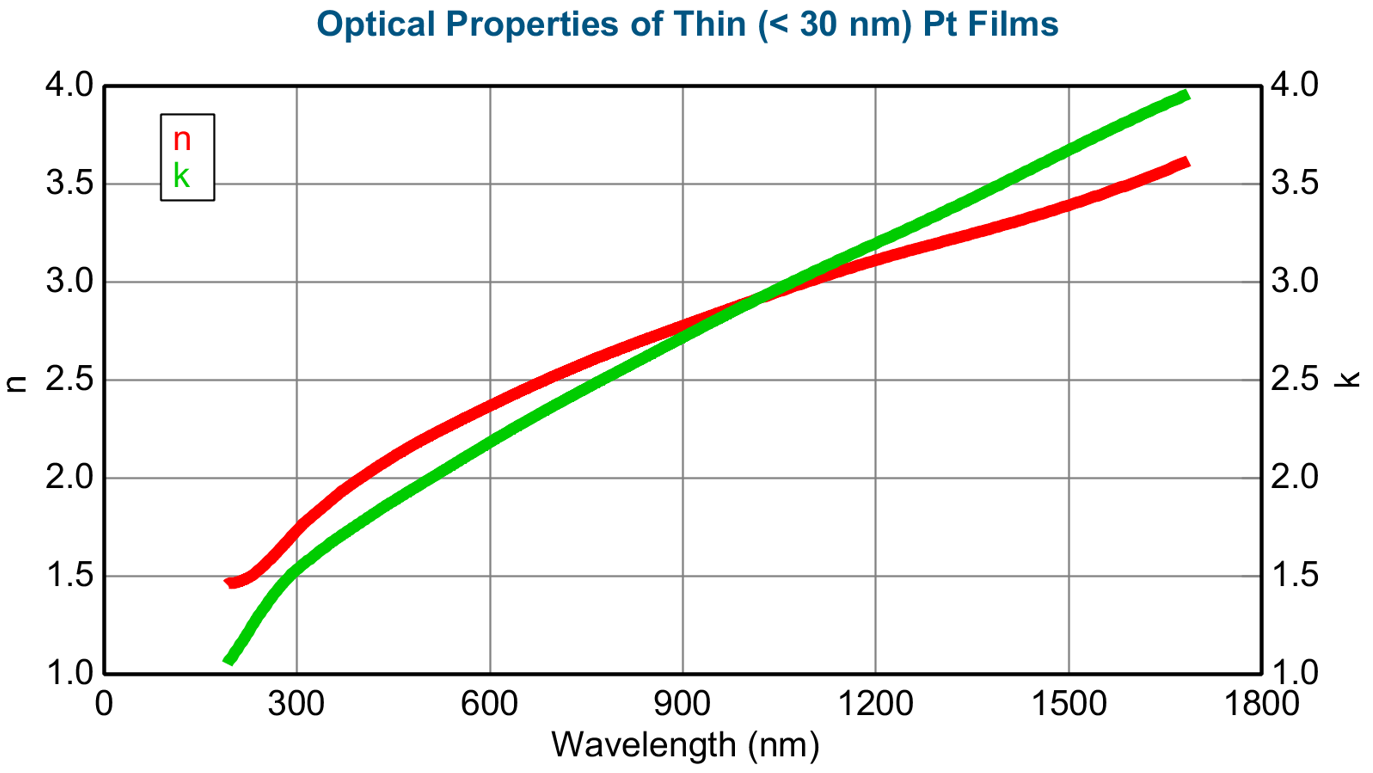

Example optical properties for partially transparent (< 30 nm) Pt thin films

J.A. Woollam RC2-DI

- Spectral Range: 193 to 1690 nm (0.73 to 6.42 eV; 1075 total wavelength bands)

- Dual-rotating compensator configuration (PCRSCRA configuration)

- Automated mapping up to 300 mm substrates w/ fully customizable X-Y resolution and scan pattern

- Measurement Beam Diameter: 5 mm (standard); or 300 µm (focused)

- Full Muller matrix measurement capability

- Variable-angle transmission stage (45° – 90° angle-of-incidence range)

In an SE system, a beam of set wavelength and known initial polarization state is either reflected by (or transmitted through) the sample to be measured.

A detector measures the changes to the beam’s polarization state vectors induced by interactions with the sample. This produces a raw data set capturing polarization at each measured wavelength; however, this is almost always the starting point of analysis.

In order to determine many properties of interest, Advanced Modeling is required. This involves computationally fitting thickness and optical properties of layers in the sample to the raw spectra, enabling indirect determination of these material attributes, and numerous other more abstract characteristics (such as: surface roughness, interfacial layers, diffusion profiles, composition, crystallinity, and more).

Ultraviolet Visible Near Infrared Spectrophotometry (UV-Vis-NIR)

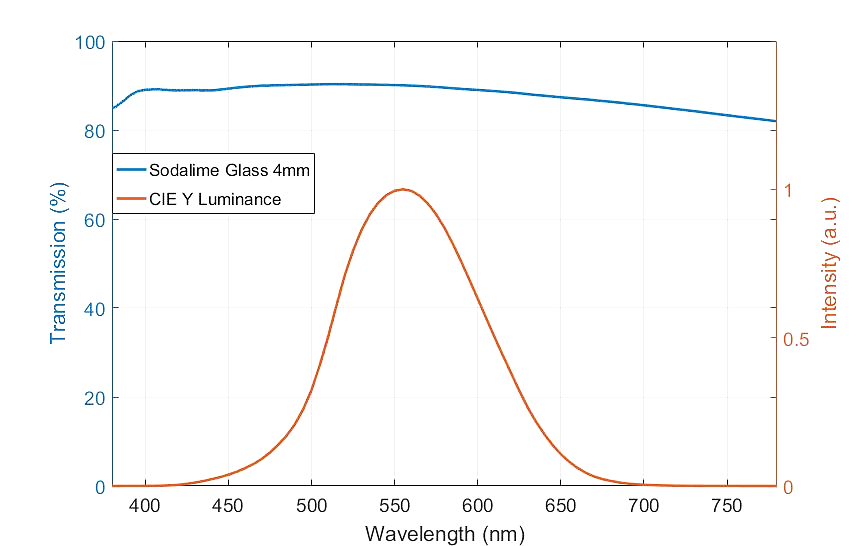

Ultraviolet-Visible-Near Infrared spectrophotometry (UV-Vis-NIR) is a non-destructive, non-contact optical characterization technique used to measure reflectance, absorbance, and transmittance...

X-ray Reflectometry (XRR)

XRR is a non-contact, non-destructive x-ray characterization technique suitable for both amorphous and crystalline materials. It provides refined...

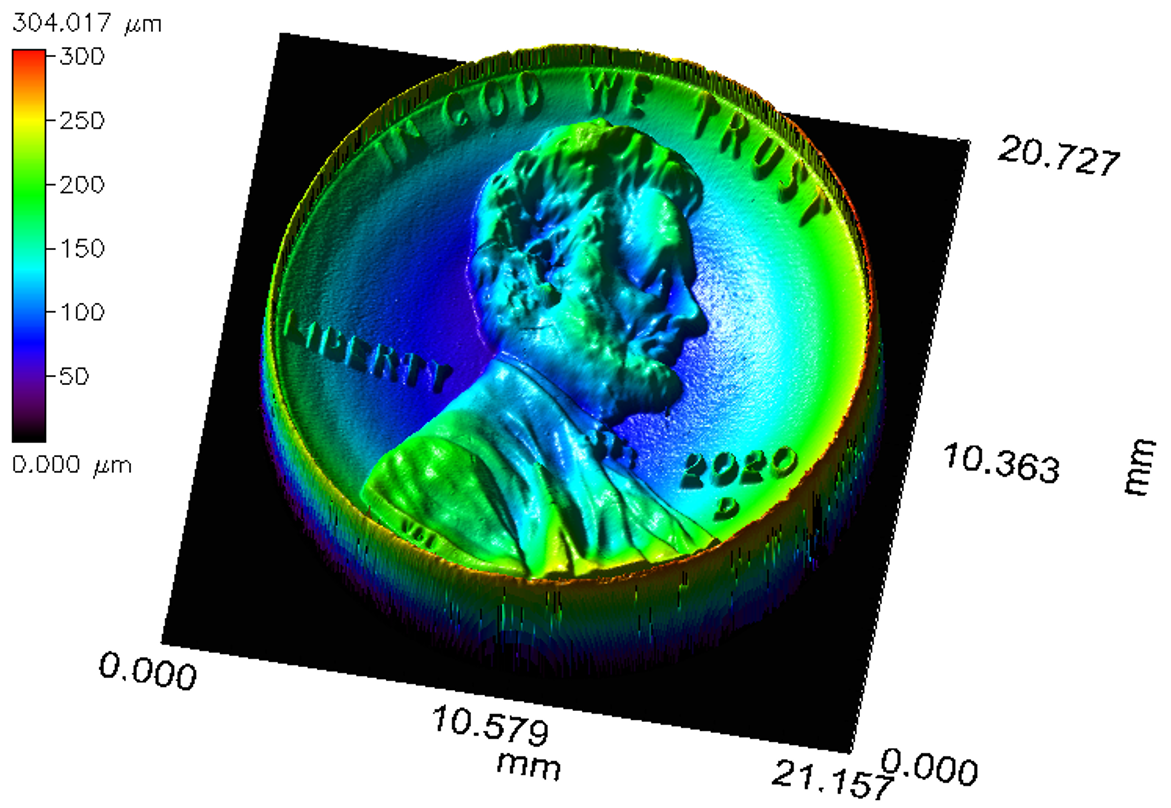

Chromatic Dispersion Profilometry (CWL)

Chromatic dispersion profilometry is a non-contact, nondestructive analytical technique used to measure surface topography. It is particularly well...

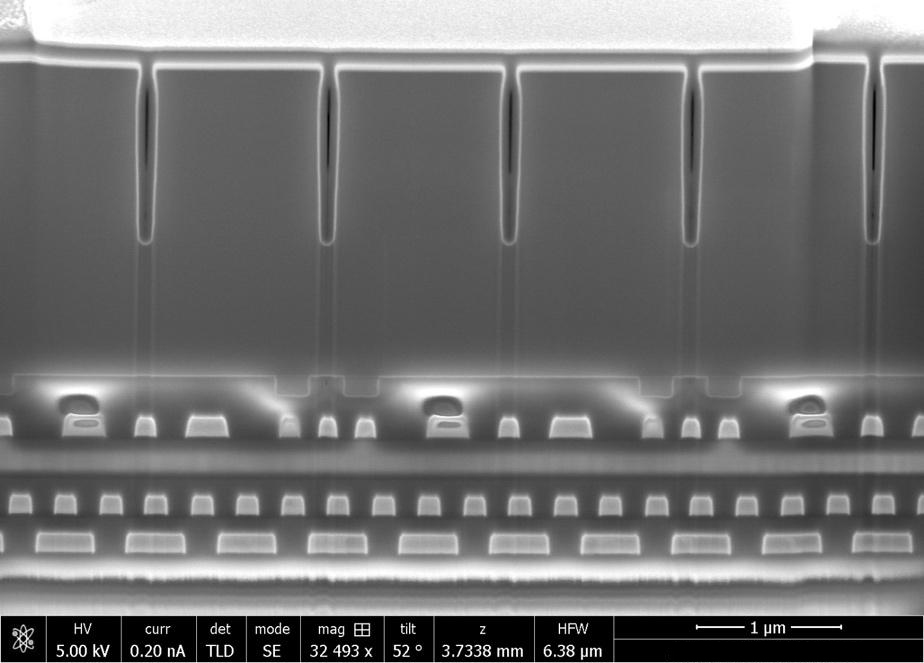

Focused Ion Beam Scanning Electron Microscopy (FIB-SEM)

FIB-SEM systems are used to produce 2D and 3D images of surface topography, and are able to resolve...

Transmission Electron Microscopy (TEM)

TEM is the highest-resolution imaging technique available today. It is used to visualize sample features with atomic-level spatial...

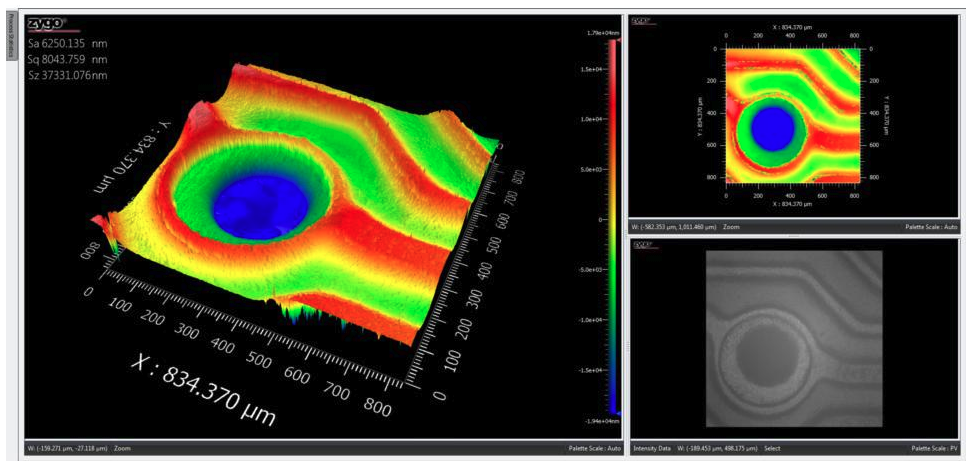

White Light Interferometry (WLI)

White light interferometry (WLI) is a nondestructive, non-contact, optical surface topography measurement which uses coherence scanning interferometry to...