Attenuated Total Reflectance (ATR)

$99 Base price View My Quote RequestX-ray Reflectometry (XRR)

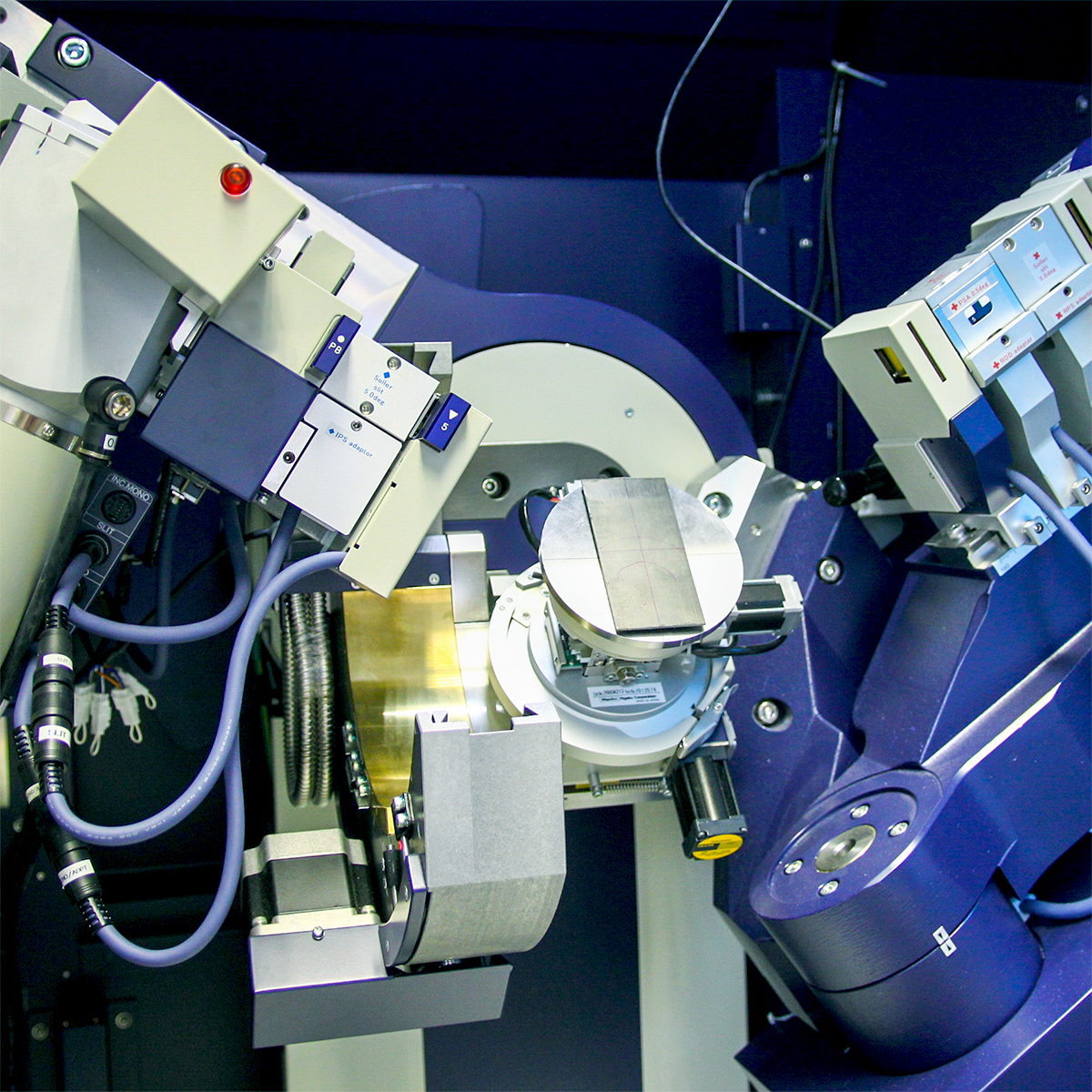

X-ray Reflectometry (XRR) is a non-contact, non-destructive x-ray characterization technique suitable for both amorphous and crystalline materials. It provides refined film thicknesses, densities, and interfacial roughness determinations for film stacks whose approximate chemistries and thicknesses are known.

- Highly sensitive to electron density perpendicular to surface: optimized for thin films

- Works well on crystalline, amorphous, or combination film stacks

- Nondestructive analysis

- Elemental composition of materials should be determined in advance

- Advanced modeling often required to extract critical insights

- Lateral inhomogeneities cannot be incorporated into XRR models

Technical Specifications:

Learn More:

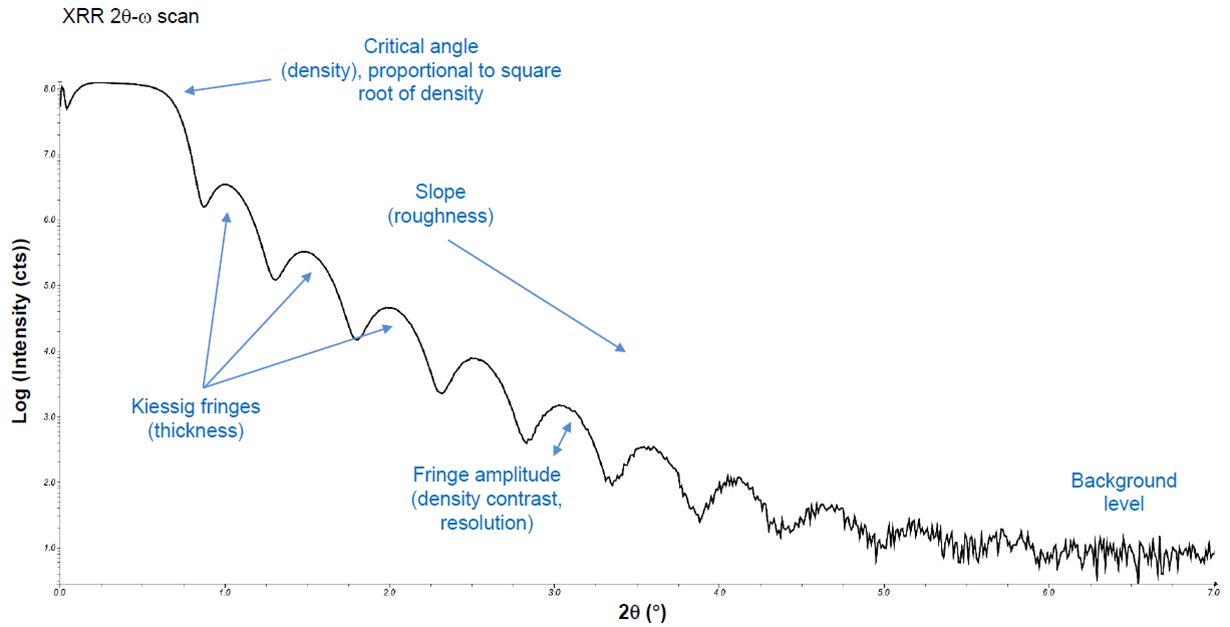

XRR pattern from Alluxa, manufacturer of high-performance optical filters and precision thin-film coatings. Annotations indicate the types of features in a standard XRR pattern, and the sample properties they inform.

Simulated XRR pattern from two different metallic thin-film layer stacks: in orange is 10 nm Au over 10 nm Al; and in blue is 10 nm Au over 10 nm Ni. These data reflect different densities in the underlayer materials (different fringe amplitudes) but an effectively identical critical angle, indicating that this value is most heavily influenced by upper, dense layers.

In X-ray reflectometry (XRR analysis) an X-Ray source supplies a high-brilliance beam of X-rays which reflect off of a flat surface at very low incident angles.

The XRR system then measures the intensity of the X-rays reflected in the specular direction (where reflected angle equal to incident angle). If the interface between layers – or between a layer and the substrate – is not perfectly sharp and smooth, the reflected intensity will deviate from that predicted by the law of Fresnel reflectivity.

The deviations of the X-ray reflectometry can then be analyzed to obtain the density profile of the interface normal to the surface and modeling can be used to determine layer thicknesses, densities, and interfacial roughnesses.

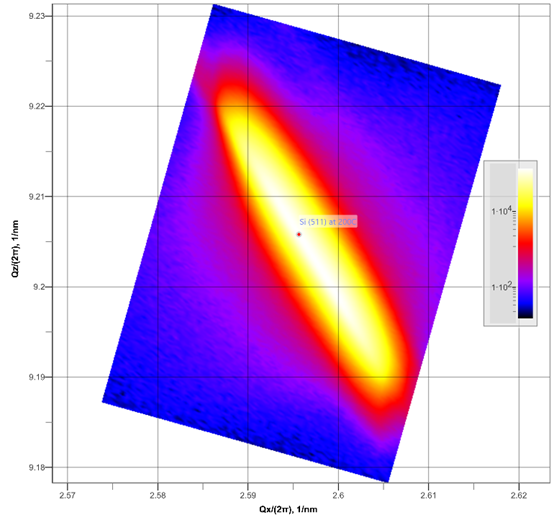

X-ray Diffraction (XRD)

X-ray Diffraction is a nondestructive analytical technique which can be used to measure both physical and chemical properties...

Spectral Ellipsometry (SE)

Spectral ellipsometry (SE) – also called “Spectroscopic Ellipsometry” – is a non-contact, non-destructive optical characterization technique which can...

X-ray Computed Tomography (Micro-CT)

X-ray computed tomography (often referred to as Micro-CT due to its spatial resolution) is a non-contact, nondestructive 2D...