Failure Analysis

When you encounter a problem or performance defect with your part or device, it can cause serious stalls in development and production. These delays cost you time and money, unnecessarily.

Working with a qualified Failure Analysis partner like Covalent can accelerate problem solving by infusing your team with actionable data and domain-specific expertise.

Our team has nearly a century of combined experience in helping teams like yours to:

- Identify failure mechanisms

- Improve production processes

- Enhance the reliability, performance, and consistency of products

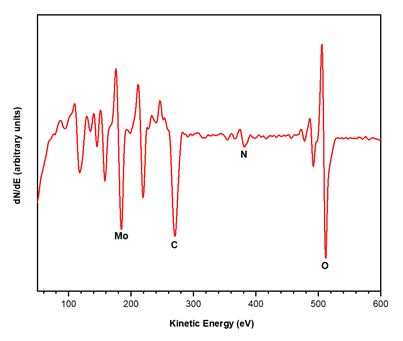

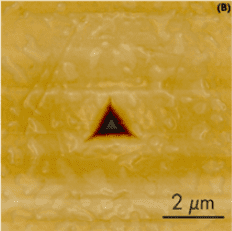

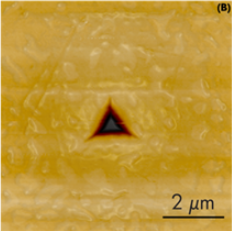

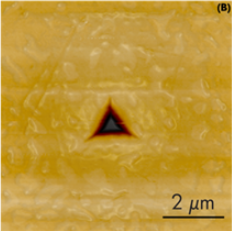

Auger Electron Spectroscopy (AES)

Auger electron spectroscopy (AES) is a surface-sensitive analytical technique with high lateral resolution. It is used to quantify and map the elemental composition of the outermost 2-10 nm of a material.

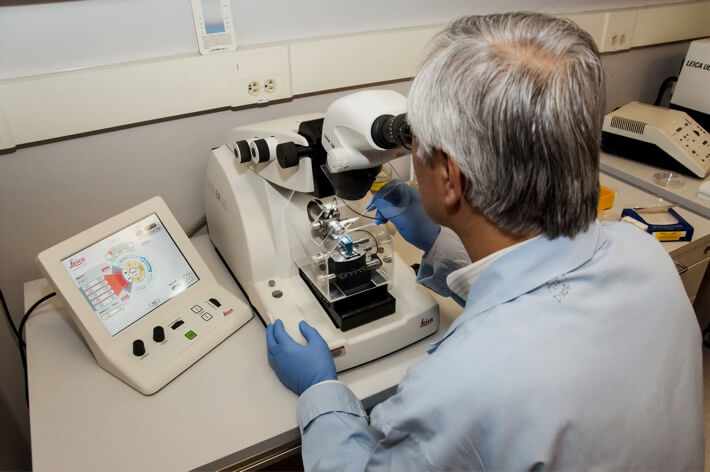

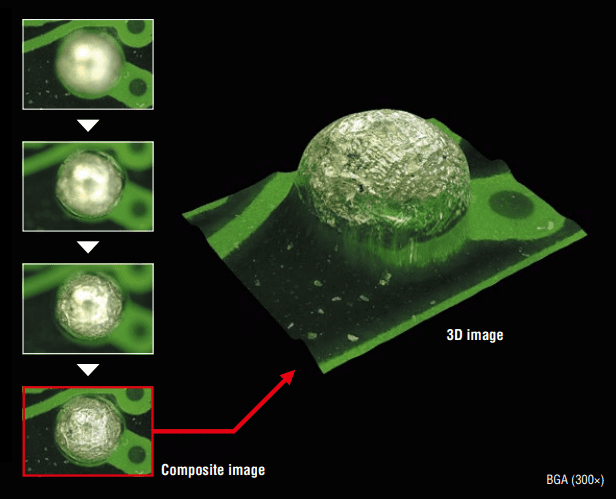

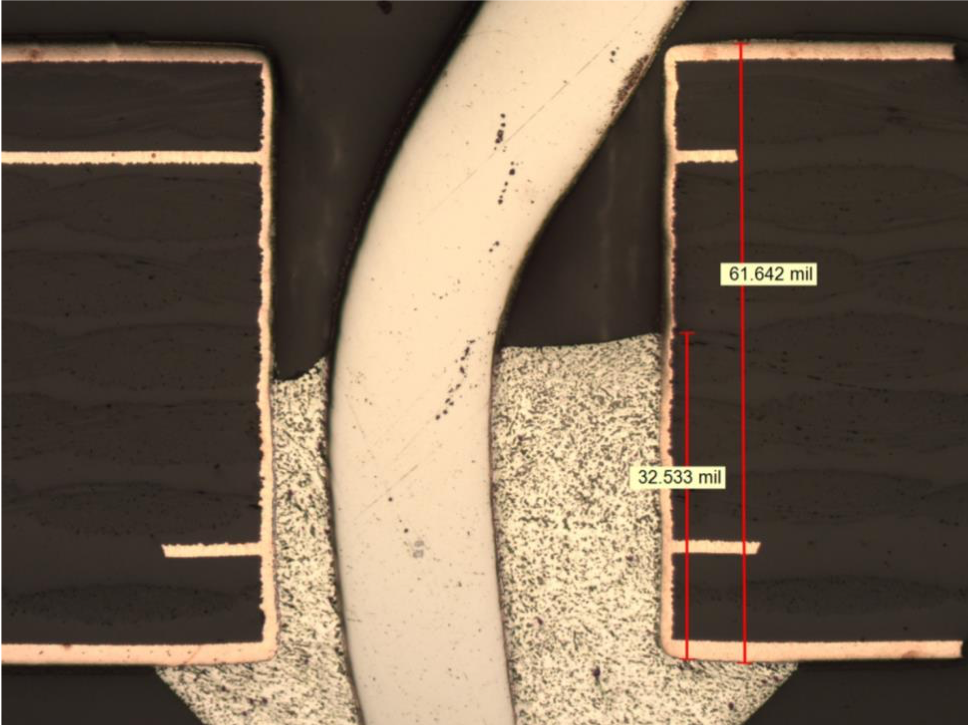

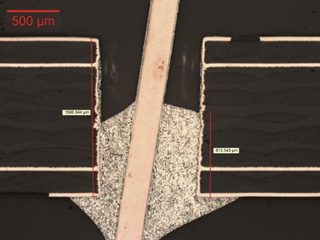

Digital Optical Microscopy (VH Microscope)

Optical microscopy is ubiquitous in diverse fields within academic research and commercial industries. It is an affordable, rapid analytical imaging technique used to visualize samples. While optical microscopes may be common, many instruments fall far short on performance when compared with the cutting-edge digital microscope systems available at Covalent.

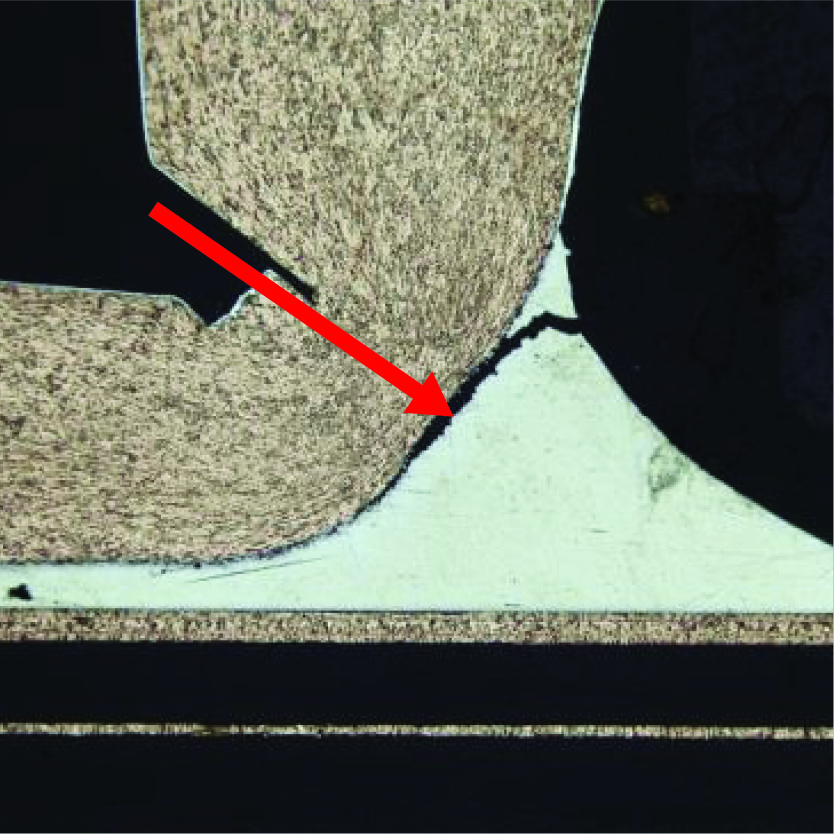

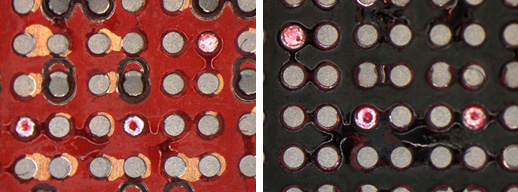

Dye & Pry Testing (Dye & Pry)

Dye and Pry testing is a destructive, IPC-prescribed failure-analysis and quality-control technique performed on solder joints on printed circuit board assemblies (PCBA) to identify certain defects unique to solder joints, such as: cracks, “head-in-pillow” defects, and other joint separations. Even when compared against X-ray analytical techniques, 'Dye and Pry' remains the most widely accepted technique for characterizing solder-ball die-attach quality defects. Our technical experts have over 20 years of experience executing Dye & Pry analysis in accordance with IPC standards.

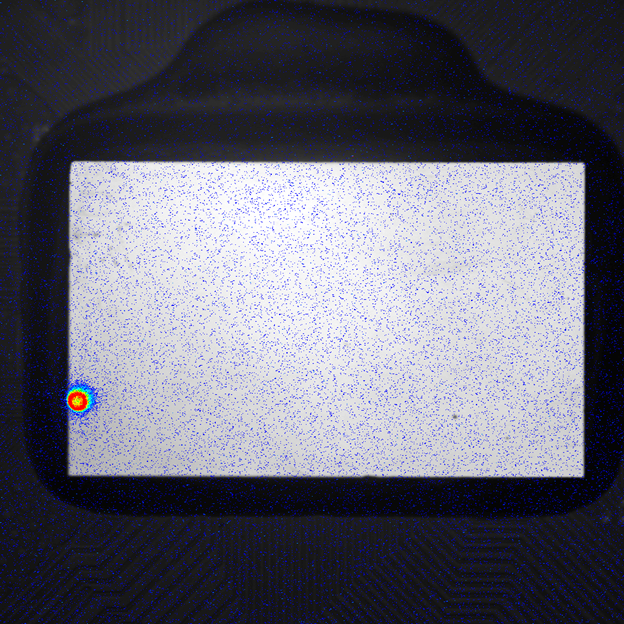

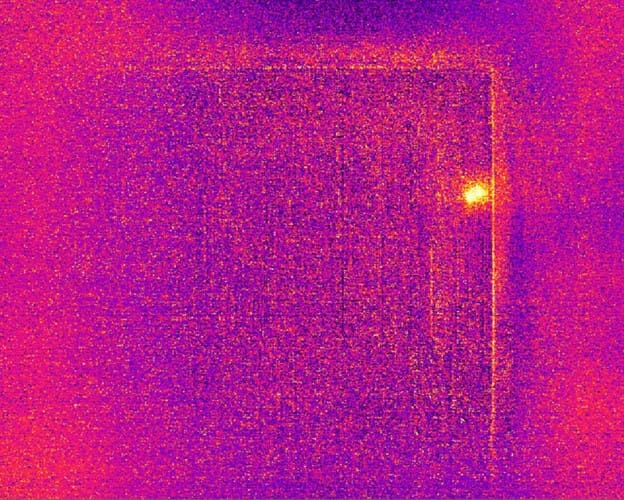

Emission Microscopy (EMMI)

Emission Microscopy (EMMI) is a non-invasive and non-destructive optical analysis technique used to localize photon emissions from fault points on integrated circuits. It is the industry-leading failure analysis technique used to isolate and analyze particular electrical failure types, such as: defective or leaky semiconductor junctions, ESD-induced damage, latch-up, and leakage current or overcurrent, among others.

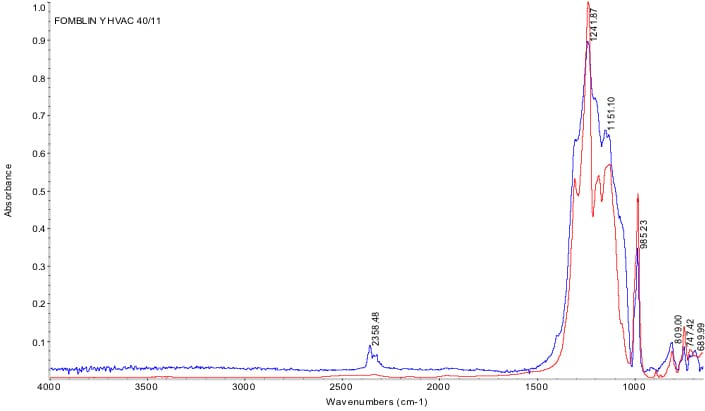

Fourier Transformed Infrared Spectroscopy (FTIR)

Fourier-transformed infrared spectroscopy (FTIR) is a nondestructive, optical technique used to analyze chemical composition and the optical properties of a material.

IPC Compliance Testing

IPC Compliance testing and destructive physical analysis (DPA) provide a comprehensive screening for quality assurance and comprise the best-known method to identify design or production issues in electronics assemblies, components, and fabricated boards. This procedure includes a complete program of analytical methods and procedures for characterizing modern electronics boards.

Infrared Thermography (IRT)

Infrared thermography (IRT) is the leading non-invasive and non-destructive method used to detect and localize material defects, short circuits, and other powered failures. It works by analyzing the heat dissipation that results from these device faults. Infrared thermography can be used to measure the heat distribution in integrated circuits (die) and printed circuit boards, and nearly any powered device to detect hot spots.

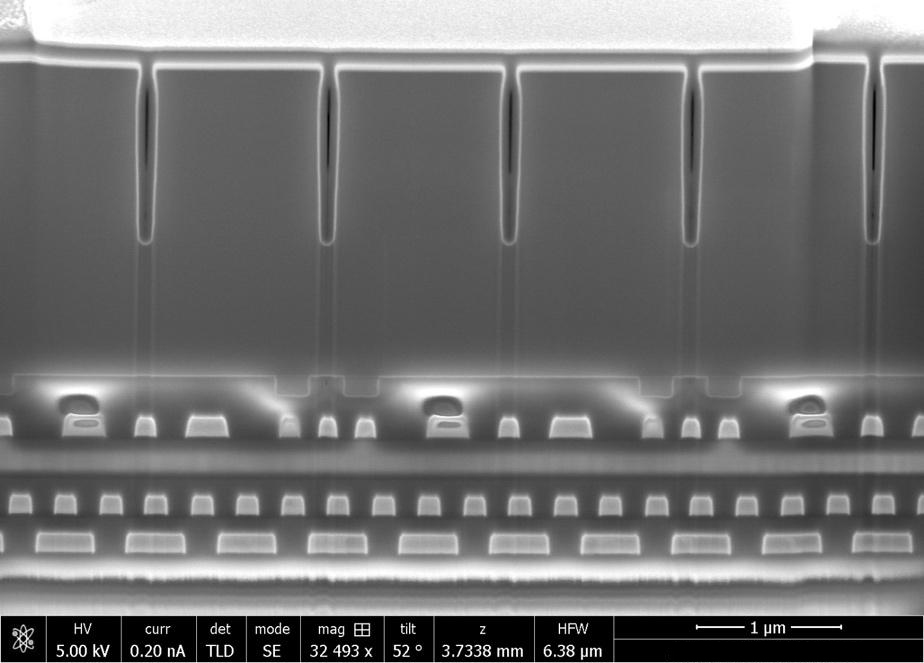

Mechanical Cross-Section Analysis

Mechanical cross section analysis enables one to expose buried features on a sample in a controlled fashion. It is regularly used in IPC compliance testing, to assay critical dimensions, or to identify miscellaneous structural defects or abnormalities such as: cracks, bridging, delamination, deformations, and more. Covalent Metrology’s technical staff have over 30 years of experience in preparation and measurement of sample cross sections. In addition, our team is certified to conduct IPC qualified cross-sectional procedures for PCB failure analysis and quality control.

Nanoindentation (Nano-Indent)

Nanoindentation (nano-indent) is a quasi-static mode of nanomechanical analysis used to measure hardness and reduced elastic modulus of solid samples. It is especially useful for evaluating thin film coatings.

Nanomechanical Scratch Test (Nano-Scratch)

Nanomechanical scratch testing (nano-scratch) is an alternate nanomechanical testing mode to nano-indent or nano-wear box testing, which is used to measure force response and mechanical properties typically of thin films and coatings.

Near-infrared Imaging (NIR)

Near-infrared imaging (NIR) is a nondestructive, noninvasive, and highly efficient method for localizing certain defects in photovoltaics and solar cells via electroluminescence. The technique is also a viable means of localizing defects in NIR fiber optic systems and lasers as well as monitoring high-temperature systems. NIR is currently seeing a growing field of application in pharmaceutical and polymers applications.

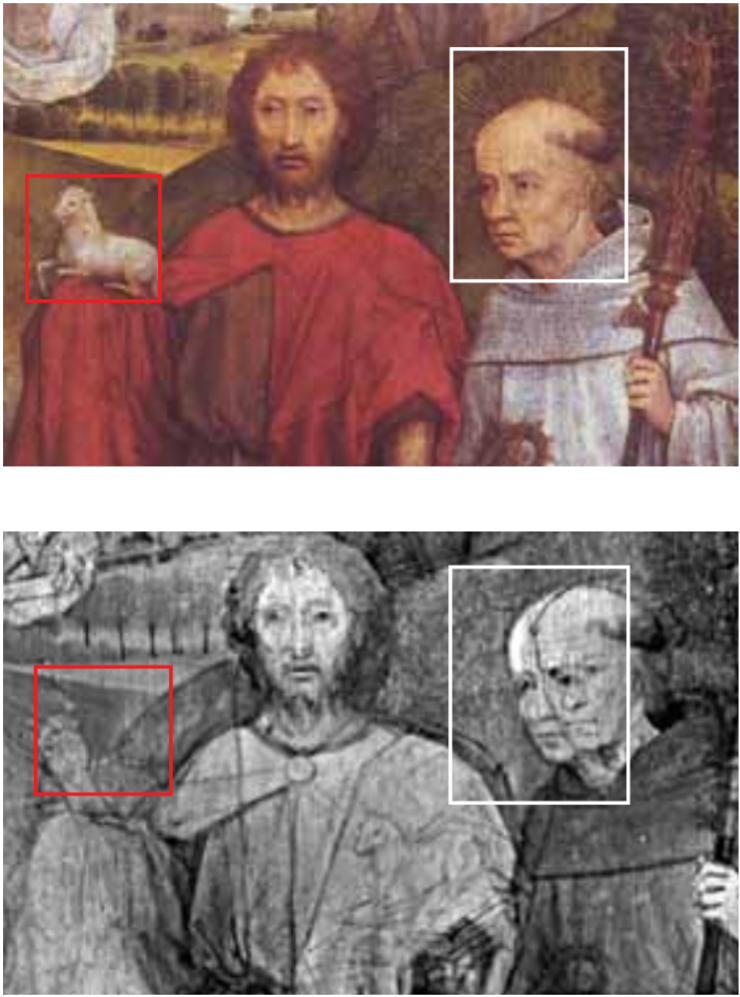

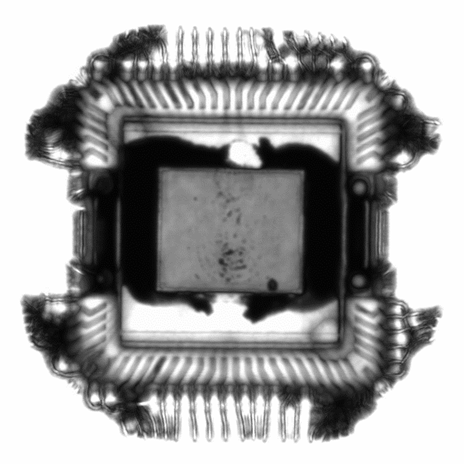

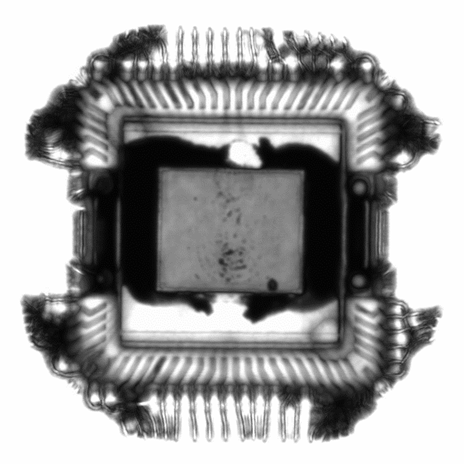

Scanning Acoustic Microscopy (SAM)

Scanning Acoustic Microscopy (SAM) is a non-destructive and non-invasive imaging technique which uses ultrasound signals to visualize the internal structures of a sample.

Techniques Showcase

Focused Ion Beam Scanning Electron Microscopy (FIB-SEM)

FIB-SEM systems are used to produce 2D and 3D images of surface topography, and are able to resolve...

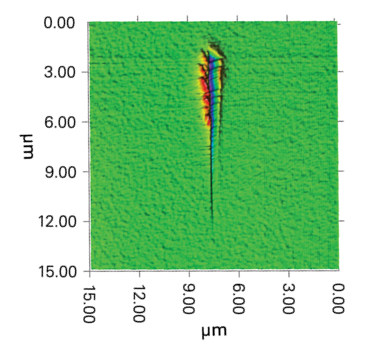

Nanoindentation (Nano-Indent)

Nanoindentation is a quasi-static mode of nanomechanical analysis used to measure hardness and reduced elastic modulus of solid...

Scanning Acoustic Microscopy (SAM)

Scanning Acoustic Microscopy (SAM) is a non-destructive and non-invasive imaging technique which uses ultrasound signals to visualize the...

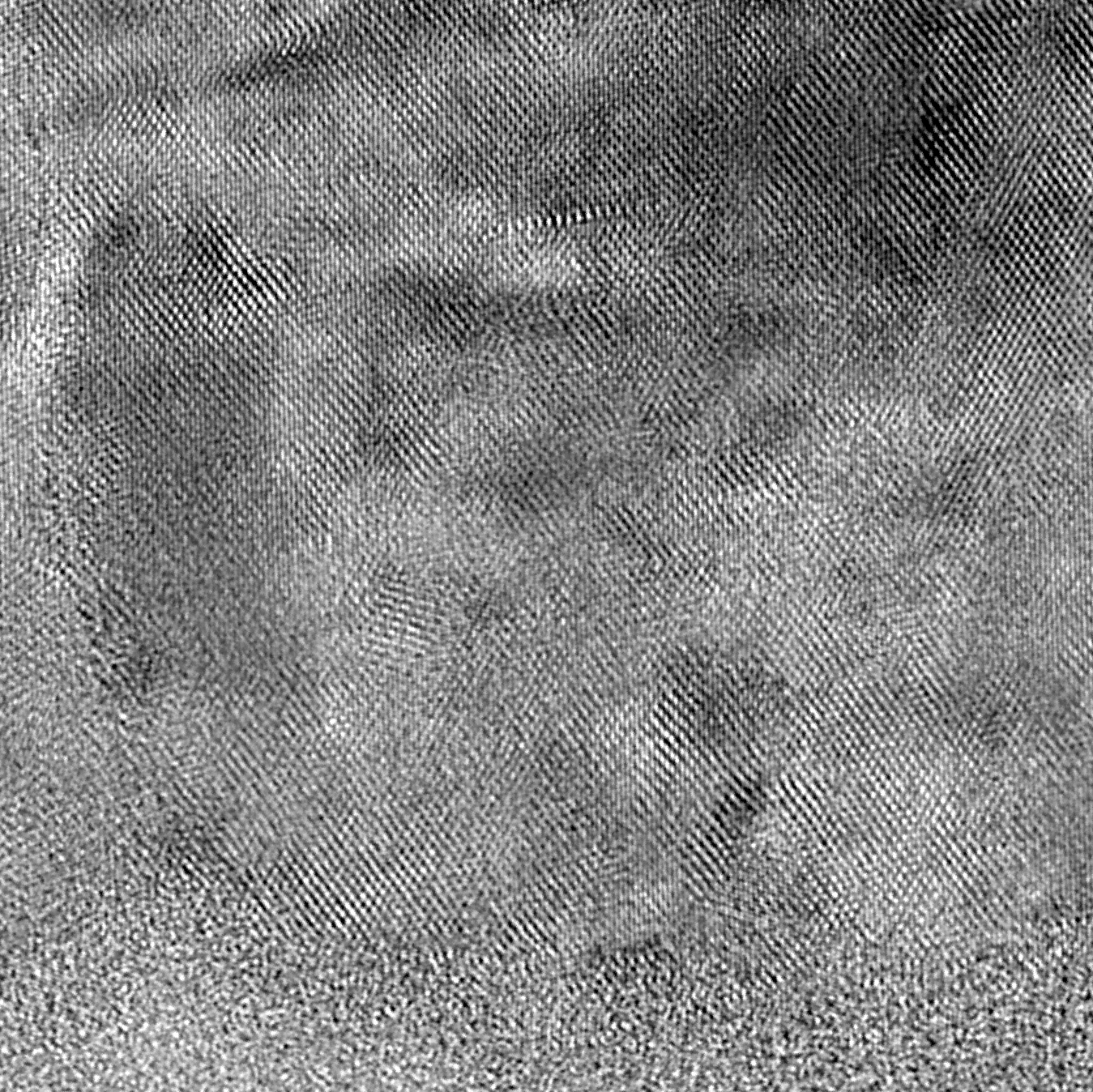

Scanning Transmission Electron Microscopy (STEM)

STEM is a hybrid electron microscopy technique used for imaging and morphological characterization with atomic-scale resolution. In Covalent's...

Transmission Electron Microscopy (TEM)

TEM is the highest-resolution imaging technique available today. It is used to visualize sample features with atomic-level spatial...

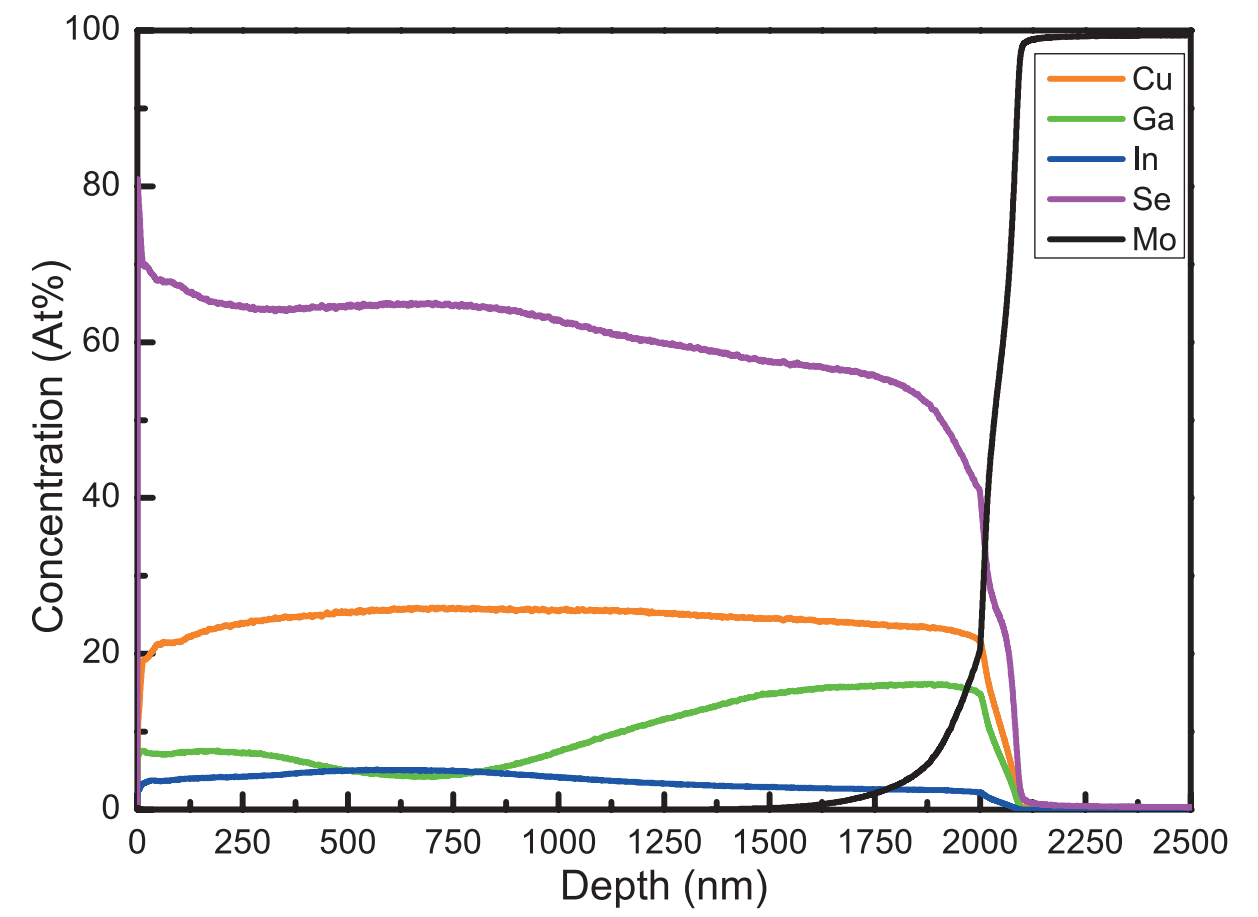

Glow Discharge Optical Emission Spectroscopy (GDOES)

Glow discharge optical emission spectroscopy (GDOES) is a quantitative, chemical analytical technique used to study the elemental composition...

Inductively Coupled Plasma Mass Spectroscopy (ICP-MS)

Inductively Coupled Plasma Mass Spectroscopy (ICP-MS) is a highly sensitive chemical analysis technique which measures the elemental composition...

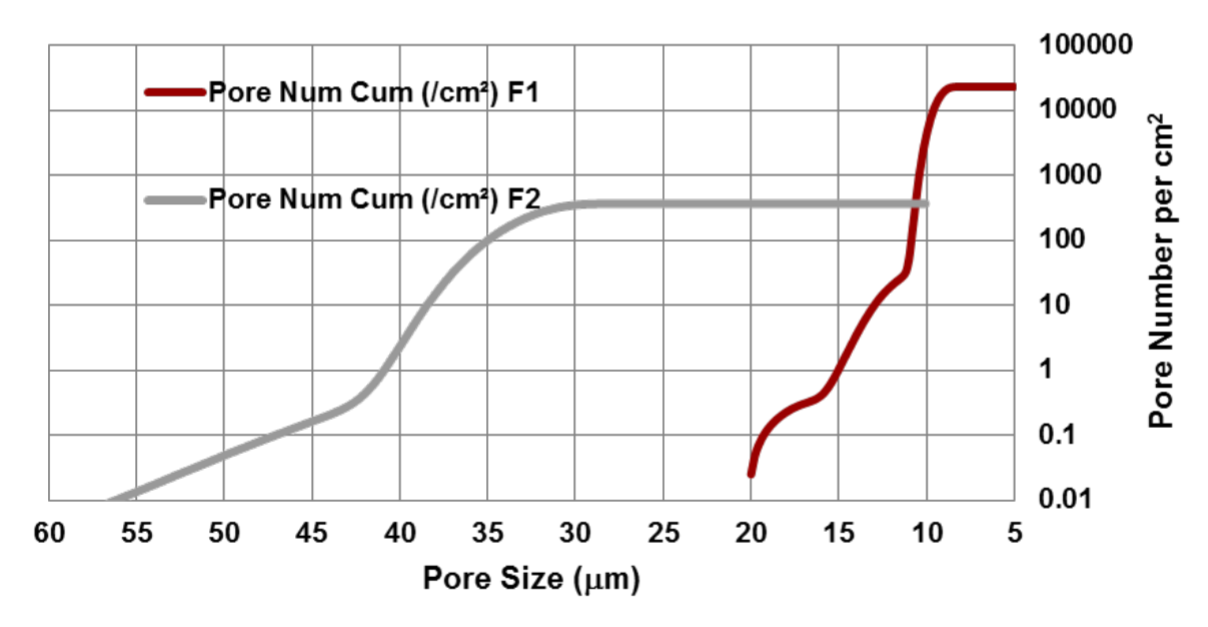

Capillary Flow Porometry (Porometry)

Capillary Flow Porometry (also called Porometry) is an optimal technique for characterizing through-pore size and size distribution.

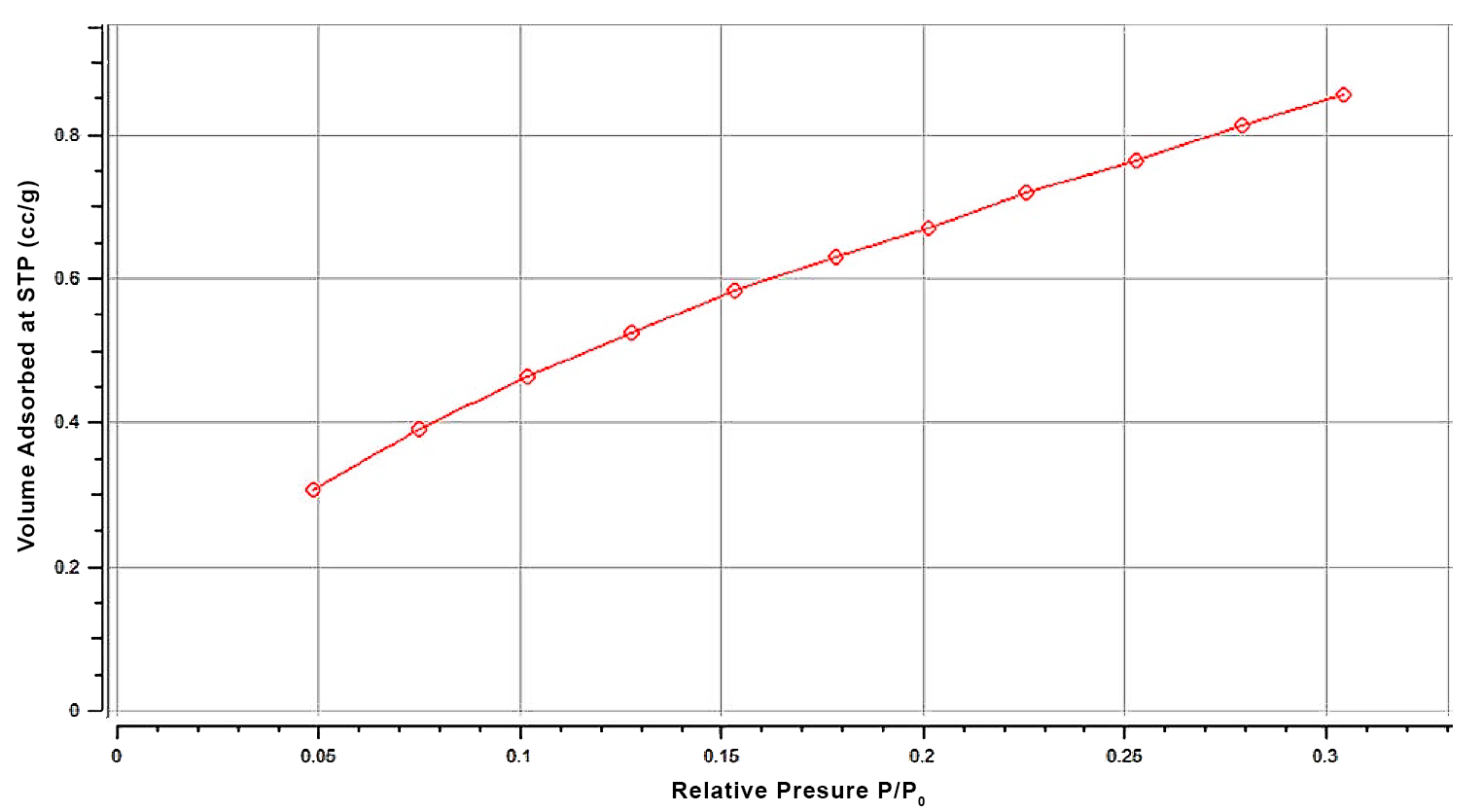

Porosimetry

Gas Adsorption Analysis is used for measuring specific surface area, pore sizes / size distribution, and overall porosity...

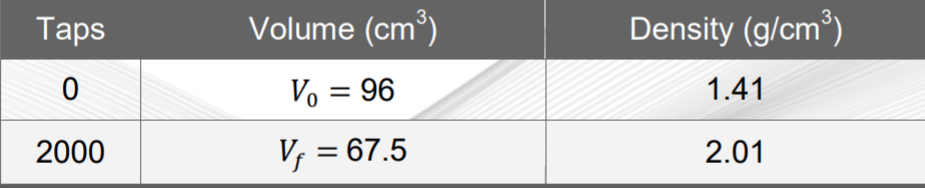

Tap Density Analysis

Tap Density Analysis provides fast, effective measurements of the bulk density of powders and establishes a quantitative metric...

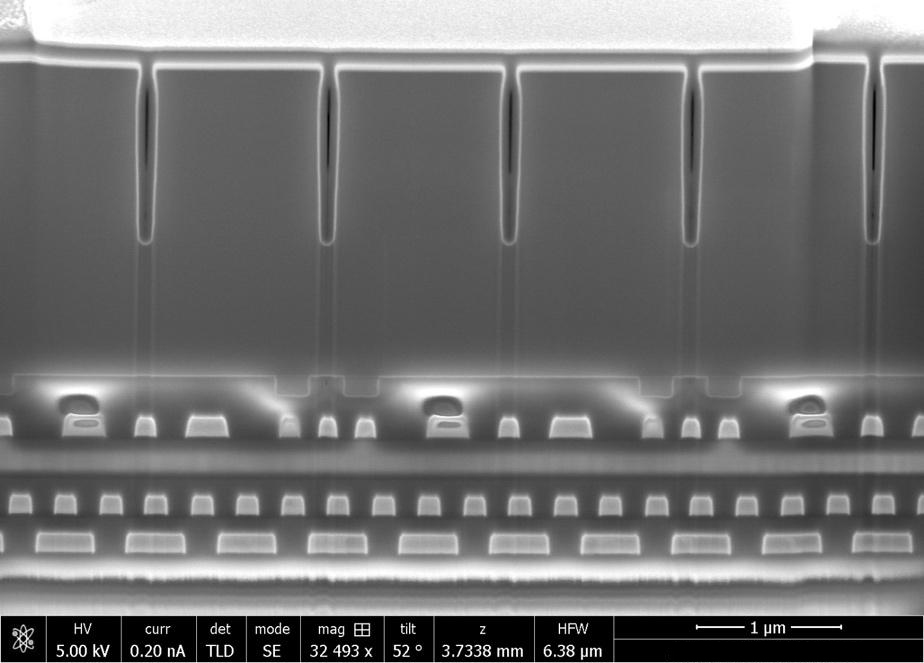

Focused Ion Beam Scanning Electron Microscopy (FIB-SEM)

FIB-SEM systems are used to produce 2D and 3D images of surface topography, and are able to resolve...

X-ray Computed Tomography (Micro-CT)

X-ray computed tomography (often referred to as Micro-CT due to its spatial resolution) is a non-contact, nondestructive 2D...

Nanoindentation (Nano-Indent)

Nanoindentation is a quasi-static mode of nanomechanical analysis used to measure hardness and reduced elastic modulus of solid...